Bearing, which is broadly utilized in machinery industries, is a significant reason for mechanical associations. It is said that when there is rotation, there is a bearing. Simultaneously, as a primary method for transport, vehicle assumes a colossal job in our day by day life. In this manner, the automobile industry likewise turns into a column industry in China where bearings think a significant job. Bearing products can be seen in numerous security gadgets of vehicles, for example, the steering rigging, engine and gearbox, and so forth. As a part of bearing classification, the automotive bearings have numerous exceptional properties, for example, rapid rotation and stun obstruction which has an extraordinary impact on travelers, drivers, and security of the vehicle itself.

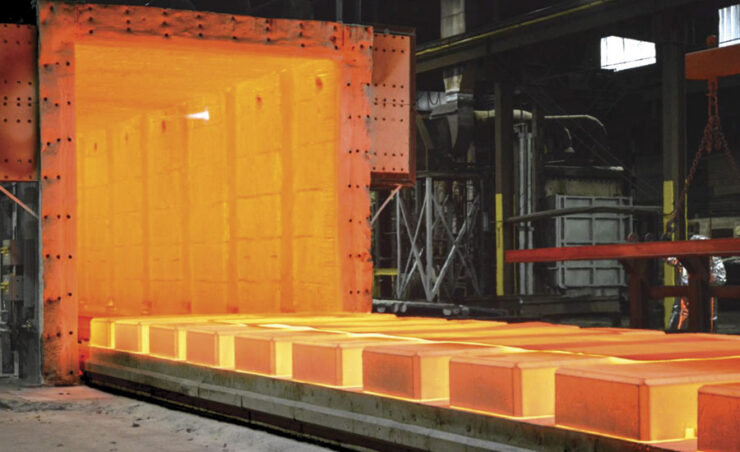

Warmth treatment is a crucial procedure during the manufacturing procedure of the automotive bearings. Its processing quality and the nature of crude materials are two significant components that influence the bearing life. If you do not understand the points of them, you can discuss that directly with a company like Songshun Steel. It can give you a technical guide in steel for all applications. The following is a short introduction of the warmth treatment innovation on the vehicle bearings. The presentation will lay premise on the automotive bearing materials, heat treatment configuration, heat treatment hardware, heat treatment innovation and the improvement patterns of the warmth treatment, and so forth. Let us see some of them.

The nature of the bearings is the most significant factor that determines the service life of the bearing products. The material is the main explanation behind the hole between China’s automotive bearings and that of outside nations. Also, the bearing structure, process level and procedure hardware are different elements. Even though China has proposed numerous valuable measures, full execution is still troublesome because we subject to multiple components like local steel smelting innovation and expenses.

With the broad utilization of vacuum degassing, the control of the oxygen substance of our bearing prepares has extraordinarily improved, which is near extreme measures. Be that as it may, there is as yet an enormous hole in the consistency of carbide, and carbide arranges control. Every one of them leads to the defect of local automotive bearings. Thus, the service life, dependability, and consistency of bearings are inferior to remote bearings.

There is likewise an absence of differential plans. The propelled bearing plan ought to be founded on the bearing service situations to meet the prerequisites of the actual state of bearings. Household individual and differential bearing structures are as yet insufficient. Moreover, heat treatment of bearing plan is likewise a significant factor that influences bearing life. The bearing includes four main pieces. In any case, there is as yet a limitation on the hardness structure of the bearings.

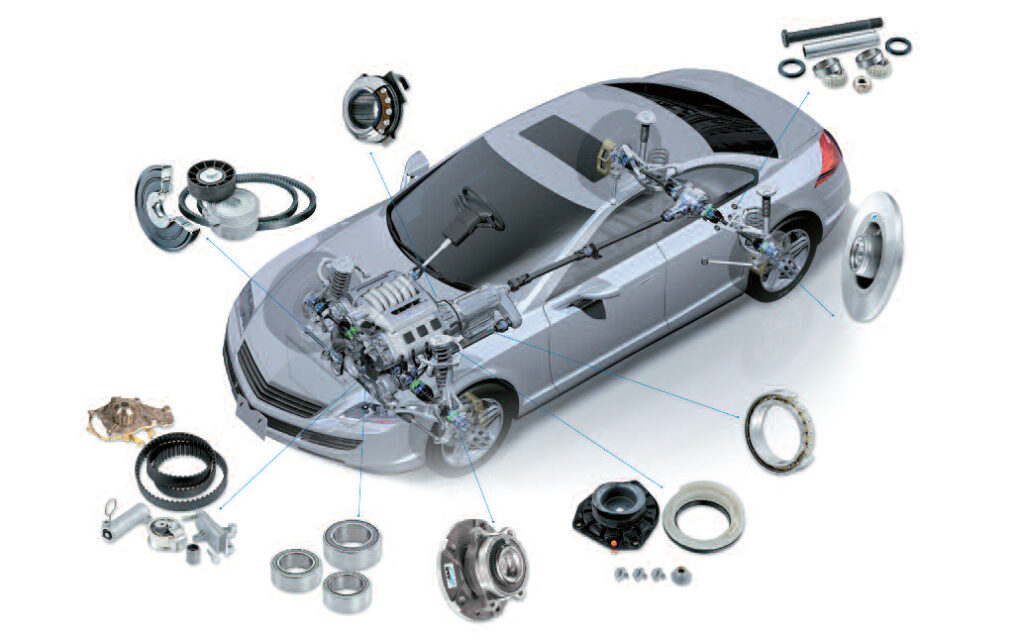

Bearing Products in Automobiles

It is known to every one of that bearings have a full application in automobiles. Their use is from the engine, skeleton to the electrical get together. By and large, automotive bearings are isolated into two classifications, for example, sliding bearings and rolling bearings.

The first class is mainly applied in quite a while. They can be future isolated into two categories. One is the thin-walled bearing which is generally known as bearing shrubbery, and the other is the bushing which is otherwise called a copper hedge. The previous is mainly utilized for supporting the engine crankshaft and connecting bars. What’s more, the last is used primarily for supporting the camshaft shaft neck and cylinder pin. Also, they can likewise be applied in different pieces of the automobile, for example, steering knuckle bushings of the case, gear bushing and engine center point, and so forth.

The subsequent class can be generally utilized in all mechanical and electrical gathering of automobiles. There are main transmission, diverter, water siphon, fans, grasp, differential instrument, front and back haggles shaft, and so forth.

The rolling bearing has two sorts. Those are metal balls and roller bearings. According to the heaps and headings, it can likewise be separated into the spiral bearing and pushing bearing. What’s more, the outspread push bearings can shoulder both the spiral and hub load simultaneously. They can be applied in different pieces of automobiles because of various capacities.

Transmission shaft is commonly bolstered at the two finishes. As a rule, there is a fixed side bearing at one side to shoulder both the spiral and hub load. It can fix the hub uprooting between the fixed shaft and gearboxes. The opposite side of the bearing is called free side bearing, which can endure the spiral burden. Relative pivotal development can be accomplished to take care of issues came about because of the activity of transmission gears and the mistakes produced during installation.

Bearing products can be additionally partitioned into different kinds according to various order strategies. While depending on the contact type, they can be ordered into two significant gatherings, be specific, sliding bearings and rolling bearings.

The sliding bearing can speak to both the hydrodynamic grease bearings requiring oils that consequently structure the oil film in the space between shaft An and bearing B by method for rotating the pole and the hydrostatic oil bearings requiring ointments that lifts the rotating shaft by providing the pressurized oil from outside.

Moreover, they can likewise speak to both oneself lubricating bearings made of original material that requires no ointments between shaft An and bearing B and the ones made of porous material to be doused with greases. Presently let us talk something about oneself lubricating sliding bearings.

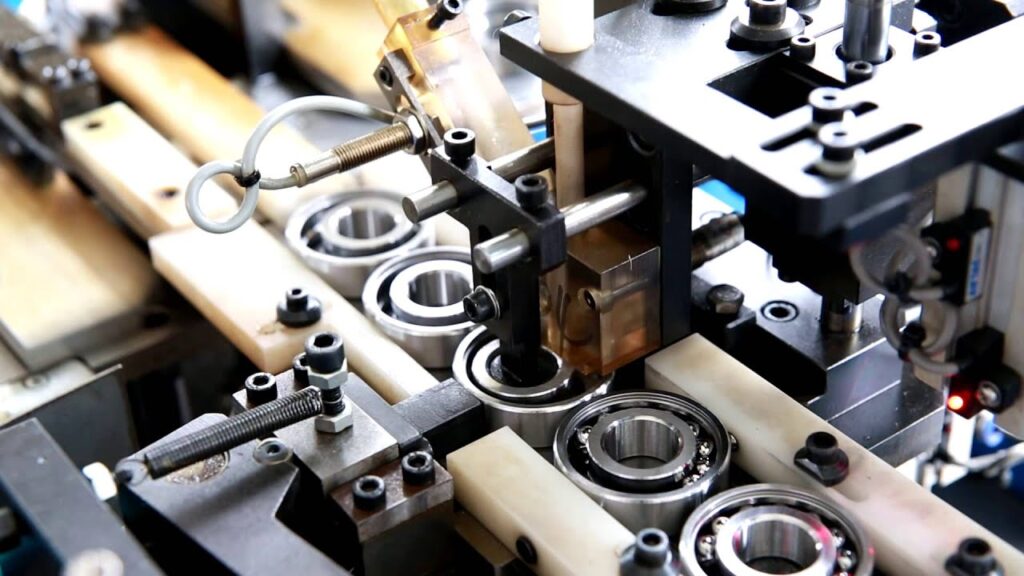

With the advancement of the innovation, there is an ever-increasing number of necessities for the presentation of the bearings. Indeed, even zero maintenance is required under serious to extreme conditions just as under most extreme burdens. The steady weight on costs furthermore calls for increasing uptime of machinery and hardware and uncompromising guidelines of unwavering operational quality.

Sans maintenance, self-lubricating, rock-solid rubbing materials delivered for bearings of the automotive industry offers bearing arrangements ensured to work dependably and securely over the long haul. In this manner, oneself lubricating sliding bearings are produced to meet extraordinary necessities.

Self-lubricating composite sliding material produced by using a continuous hot rolling sintering innovation which increases the unwavering quality and service lifetime of the sliding plates altogether. It is portrayed by high wear obstruction, insensitive to affect pressure and impervious to unforgiving operational and encompassing states of mechanical and concoction condition.

It typically requires no oil and permits maintenance free. It is reasonable for rotational, oscillating and linear developments. These bearing materials add to upgrade execution and ideal qualities in every single industrial portion. The dry wear instrument empowers these bearings to work acceptably without customary oils.