Whether you have a brand new car or a used car passed down from your father, every car owner wants their engine to perform its best for a long time to come. However, not many owners are well versed about car engines and how to tweak engine performance in your favor.

Fortunately, you don’t need to be an engineer or a mechanic to understand engines. Some basic knowledge and our comprehensive guide will give you an idea about how to take care of your engine and keep it in its best shape. So buckle up your seat belts and let’s start driving.

Page Contents

How Long Should Engines Last?

Lasting over 100,000 miles is the standard for modern engines, and with proper care, figures over 200,000 miles aren’t unnatural either.

However, achieving these impressive figures is only the result of good care. A properly maintained engine can easily get you a decade of use, whereas poor care will cause it to break down well before its usual lifetime.

When to Seek Help for Engine Problems

If your check engine light is flashing, it might be a sign that something is wrong with your car’s engine. You should go to an auto parts store and get your car diagnosed in such cases. Check out mechanicbase.com to learn what else you need to do when this happens.

Some centers even check other elements to identify any issues. There is a huge improvement in diagnostic tools for cars because of modern technology. Nonetheless, be alert and seek a mechanic if one of these things happen:

- Engine light is flashing

- Engine makes any strange sounds on acceleration

- Engine feels shaky

- Fluid leaks from your car

- Smoke from under your hood

- Excessive or blue exhaust from the exhaust pipe

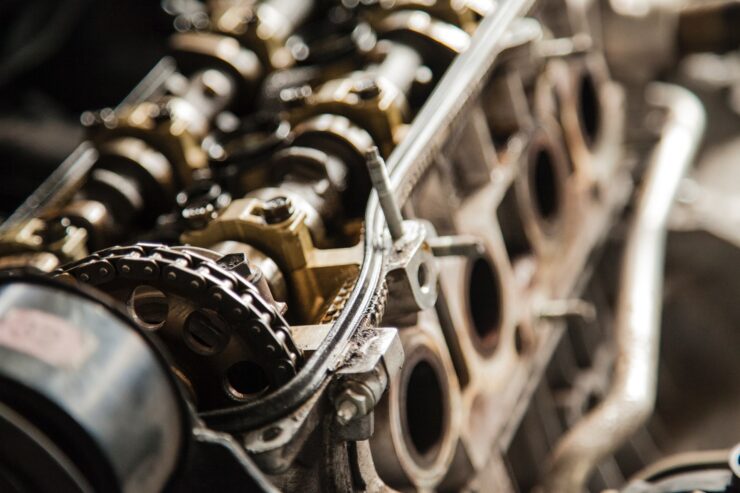

Why an Engine Loses Power

Normal wear and tear due to driving are the most common causes of power loss in an engine. This includes damaged, clogged, or dirty components, malfunctioning sensors, and dirty air filters. Any problem with the fuel injectors, spark plugs, compression, spark, air, or fuel of the engine can also reduce engine power.

Importance of Engine Performance

You are late for work and suddenly your engine won’t start or, worse, you are on a road trip and your engine breaks down on an empty highway without a soul in sight. No one wants to be part of either of these terrible scenarios.

Even if you don’t use your car much, loss of engine performance indicates that all is not well under your car’s hood. Checking your engine performance can help you identify other problems that can be fixed early on. It is always cheaper to change certain parts of your car over buying a new car. If you want your vehicle to stand the test of time, you need to pay attention to its maintenance.

Improve Engine Performance

Good and persistent engine performance is something all car owners want. However, oil changes and tune-ups alone aren’t enough. Here we discuss the numerous ways to keep your engine revving up for a long time to come.

Synthetic lubricants

Friction is inevitable when driving, and synthetic lubricants are used to avoid the risk of damaging your engine’s internal parts. Synthetic lubricants are preferred over conventional oils because they are heat and stress-resistant. They also have low-temperature pump ability as well as protection against extreme temperatures and deposits.

Ignition

The “check engine” flashlight shouldn’t be your first indication to check the ignition system. Look for good-quality coils, ignition wires, and platinum tip spark plugs when replacing ignition parts.

Choose original equipment quality or, at the very least, exclusive replacement parts like MSD for flawless ignition functioning. This helps improve horsepower and reduce tailpipe emissions, loss of power, and wasted fuel.

Ignition timings are best set at a total timing of 2500 rpm and starting efforts at 32 degrees BTDC (before top-dead-center) with a road test or dyno pull. Then change the timing by one degree at a time–33, 34, 35 and simultaneous road/dyno testing without exceeding 36 degrees BTDC.

These limits are set to prevent detonation. Contact a professional to dial in both ignition and fuel maps so you get power for ignition timing. They know how to do so without damaging your engine.

Larger Throttle Body and Injectors

This helps you achieve a higher horsepower as high as 10-20 as well as comparable torque. However, too large throttle bodies can have the opposite effect. Research to find out whether your engine is suited to a large throttle body.

Keep in mind that throttle body and injector size are proportional. Find a capable dyno tuner who will help to fine-tune your throttle body/injector upgrade by making the adjustments to fuel and spark curves.

Compression Repair With Ring Seal

The most productive way to increase horsepower is by increasing compression. Although this is an obvious way to improve performance, you should also be careful about other aspects that can affect working compression or cylinder pressure such as cam selection.

Compression and cam selection should be coordinated, and the engine builder knows the best combination. For example, compression of more than 10.0:1 can lead to spark knock, pre-ignition pinging, or worse, detonation. Observe your fuel and spark curves when bumping compression.

Choose fuel that seals and repairs cylinder walls and microdamage as well as re-seals rings around the pistons. This is usually best achieved by the pricey high octane, smog-legal unleaded fuel.

Intake

This is the beginning of engine performance. First, air mixed with fuel produces power in the engine. Intakes with fewer restrictions slow air down thus reducing the air pulled by the engine at a time. This allows more power to be produced by the engine.

Turbochargers and Superchargers

Turbochargers and superchargers are compressors to mix more air with fuel by pressurizing the incoming air which drastically improves the power output. Despite the costly process of turning a conventional engine into a forced induction setup, both turbochargers and superchargers are now popular additions.

Found-Bonus Power

Because of internal friction, a large amount of power is required just to move components. This is why despite producing a lot of power, it delivers much less resulting in poor engine performance.

You can lose up to 75 percent of the power as heat with 50 percent out the tailpipe while 25 percent through the cooling system. With only 25 percent of the fuel’s BTUs (British Thermal Units) used for driving the engine, the engine’s efficiency is drastically reduced.

Here are some ways to counteract that:

- Needle-bearing cam sprocket

- Roller tappet camshaft

- Low tension piston ringsRoller rocker arms

- Dual-roller timing set

- Greater valve-to-guide clearances (within limits)

- Greater piston-to-cylinder wall clearances (within limits)

- Windage tray (oil windage at high rpm robs power)

- Greater bearing clearances (within limits)

- However, there’s always the risk of losing something in any modifications.

- Another culprit that drains the power is the car’s driveline. Tire inflation and tire/wheel sizing are other causes of the sluggishness. You need more power if your car’s contact patch is large.

- On the other hand, underinflated tires will make it feel like driving against resistance.

Velocity Stack

The trumpet-shaped device at the entry point of the air in an engine’s intake system, carburetor, or fuel injection is the velocity stack. Its purpose is to improve airflow. It does so by reducing induction turbulence, thus leading to an increase in horsepower.

Fuel Line Right-Sizing

Despite it being obvious, many are not aware of correct horsepower-fuel line pairings. You’re not going to get high horsepower from a narrow fuel line. This is like rapidly drawing iced tea through a cocktail straw. The minimum fuel line size should be 3/8-inch for most applications. For horsepower above 500, you need a 7/16-inch fuel line.

Dual Plane Manifold

Unfortunately, the obsession with horsepower means that torque often gets ignored. To hand off torque smoothly to horsepower at wide-open throttle you need a dual-plane manifold.

This allows for low- to mid-range torque as well as lets the engine run at high rpm. So this results in greater torque with high horsepower figures during acceleration. The lengthy intake runners of the dual-plane manifold are important for torque, while the high ceilings aid supply horsepower. Remember that you can also use a carburetor spacer for even more torque out of a traffic light.

Experiment With Jet Size

Use a Holley jet kit and experiment with different jet sizes going small amounts at a time to see the changes in power. Go back one jet size at a time if you are losing power going rich. Try to get a spark plug reading simultaneously with a wide-open throttle shutdown to determine the course of action.

Remove the carburetor if it is running with a fuel line screen at the fuel bowl. This is because the in-line fuel filter is sufficient so won’t have to worry about fuel supply.

Cylinder Head

With a huge selection of cylinder heads, it is very easy to improve engine performance. Before swapping your cylinder head, check the valve, port size, and flow numbers to get a good idea for the right cylinder head for you.

Size isn’t the determinant here, and huge valves and monster ports aren’t always the answer. A compatible exhaust scavenging with a good intake velocity will give you the desired torque. Also, look for a camshaft profile that complements the cylinder heads for a smooth flow-through momentum and good overlap.

Exhaust

By reducing restrictions on the exhaust, you can increase the power. By optimizing the exhaust flow to reduce backpressure, the engine expels waste fumes quickly to burn fuel faster. Performance exhaust systems are louder than stock equipment because of the high-flow mufflers.

Conclusion

Knowing your engine’s inner workings and following the tips and tricks to improve engine performance can make a dramatic extension on your engine’s lifespan.

Not only will this help you save more fuel and increase engine efficiency, but you will be more aware of what goes on beneath your hood.